We sincerely invite you to attend the 39th China International Ceramics Industry Exhibition at Hunan Zhonglian Ceramics Machinery from June 18th to 21st. Our booth is located at F211 in Hall 6.1, Area A.

Source:

Author:

Release time:

2025.04.16

Established in 2002, the company boasts two production workshops covering an area of 33,350㎡, located in the Yi Su He Tian Yi Industrial Park in Xiangtan County, Hunan Province, China. Benefiting from convenient transportation, the park is a hub for ceramic machinery industry professionals and a center for advanced ceramic machinery design and manufacturing. Our equipment is widely used in the production of daily ceramics, architectural sanitary ceramics, electrical porcelain, as well as in the chemical, papermaking, and environmental protection industries. Our complete sets of water washing production lines for kaolin, feldspar, ball clay, and alumina porcelain balls have earned the trust of numerous users. Main products include: ball mills, filter presses, plunger pumps, clay mixers, automatic cutting machines, magnetic separators, mixers, pug mills, fully automatic isostatic pressing porcelain ball forming machines, intelligent filter press mud cake conveying lines, automatic mud cake packaging systems, and wastewater treatment systems. We have nearly 1500 customers and our equipment is sold in over 20 countries.

Zhonghlian people always adhere to the tenet of "integrity-based, reputation first" and the guideline of "exploration and innovation, quality first." With first-class service, we work together to create a brilliant future for the ceramic industry.

Intelligent Filter Press Mud Section Production Line

The intelligent filter press mud section production line is mainly used for the preparation of ceramic mud materials, completing the work from slurry to mud section;

The process includes: plunger pump pulping, automatic filter press filtration, mud cake conveying, kneading, vacuum rough kneading, mud strip cutting, robot stacking, and trolley output, with an hourly mud section output of 12-40 tons (single machine configuration);

The ZYLM80/100/125 series intelligent filter press mud section production line is widely used in the daily porcelain, electrical porcelain, and professional raw material preparation industries and has been consistently recognized by users in the industry.

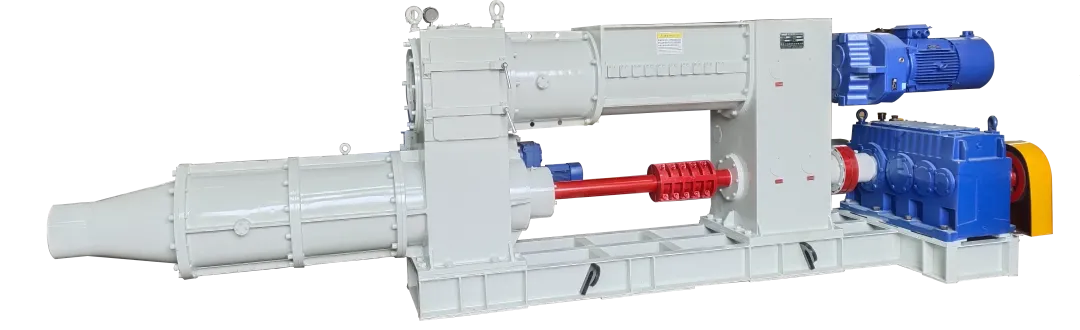

Vacuum Clay Mixer

(For the electrical porcelain and refractory materials industries)

This series of vacuum clay mixers is a mechanical equipment that processes the plastic raw materials of electrical porcelain through vacuuming and spiral pressure extrusion;

Absorbing the advantages of existing domestic and foreign vacuum clay mixers, it features direct drive and can be controlled by frequency conversion to achieve adjustable speeds, reducing the occurrence of vacuum blockage and dry mud discharge;

The upper and lower shafts and the pressing rollers are driven directly by separate hard-toothed surface reducers, resulting in a simple structure and convenient maintenance. The spiral blade uses a small spiral pitch angle, providing high extrusion pressure. This machine is an ideal equipment for the electrical porcelain and refractory materials industries.

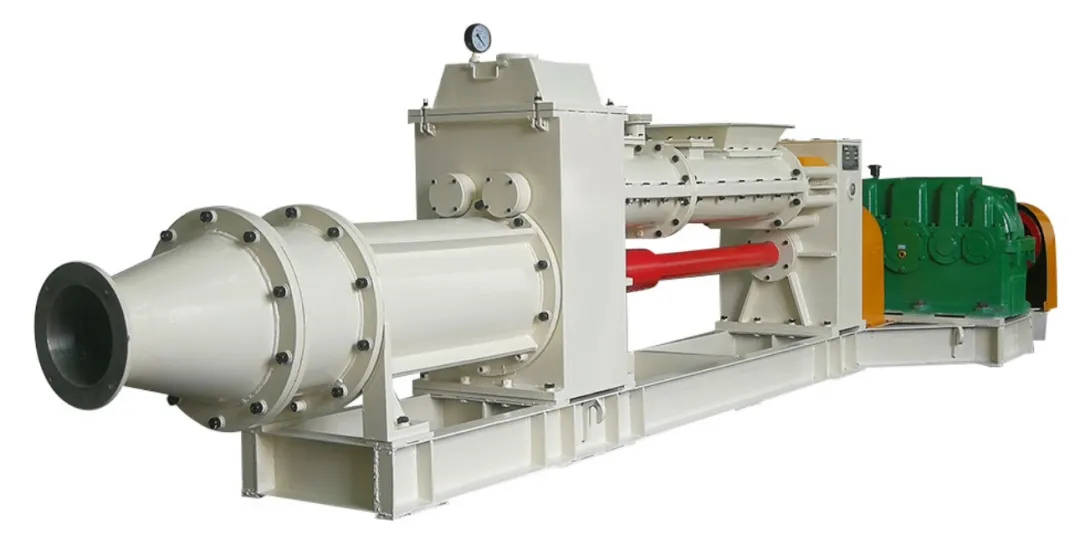

Three-Axis Vacuum Clay Mixer

The clay mixer features double stirring shafts and a two-stage vacuum structure. The parts in contact with the clay are all made of stainless steel. The double stirring shafts simultaneously cut, mix, stir, and knead the clay in the mud trough, achieving better results than a single stirring shaft;

The clay is vacuum treated in the suction seat and vacuum chamber, and finally propelled and extruded by a screw, making the clay more uniform and dense, improving its plasticity. It is an ideal equipment for kneading and extruding high-grade daily porcelain, refractory materials, honeycomb ceramics, and chemical fillers.

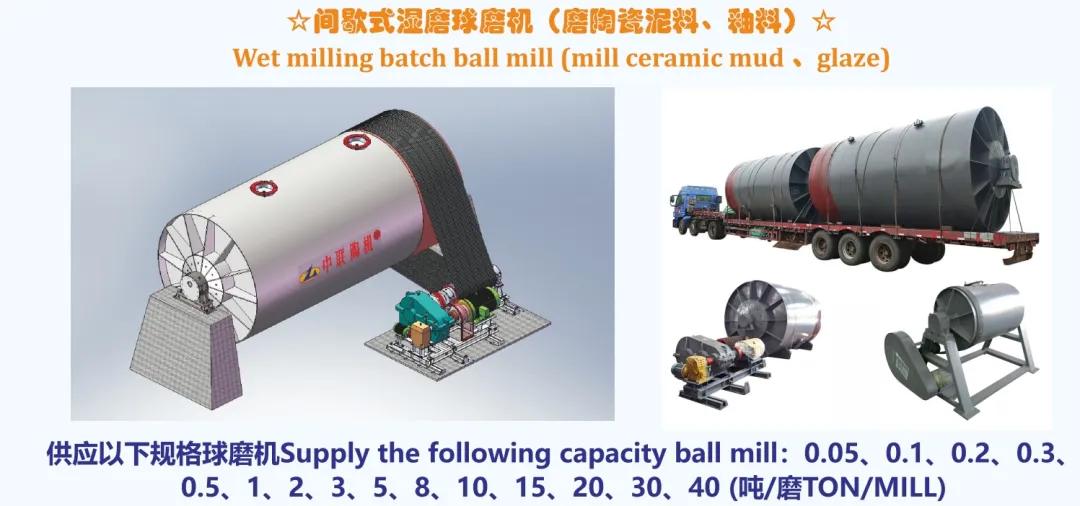

Batch-Type Wet Ball Mill

Various specifications (0.05~40MT), suitable for ball milling various ceramic raw materials, clay, and glaze, and also suitable for grinding in the chemical industry. We have over 20 years of experience in ball mill production.

High-Pressure Automatic Filter Press & Plunger Pump

Used together, the filtration pressure can reach 3.5Mpa, shortening the filtration time and achieving a minimum moisture content of 16% in the坯料. Widely used in industries with long dehydration times and high dehydration difficulty, such as electrical porcelain, daily porcelain, kaolin, and sludge.

recommend dynamics

2024-08-05

Share